Technics Grand Class Direct Drive Turntable System - SL1200GR2S

- Coreless direct drive motor achieving stable rotation

- ΔΣ-Drive suppresses vibrations from the motor for smoother, more accurate rotation

- Low-noise, low-voltage power circuit and a switching power supply

- Two-layer platter with high rigidity and vibration damping

- Tonearm achieving high initial-motion sensitivity

- High-rigidity body and high-damping silicon insulators for smooth sound and isolation from various vibrations

The improved motor-drive circuit centered on the newly developed ΔΣ-Drive (Delta Sigma Drive) thoroughly suppresses any minute vibrations generated from the motor. This is the first stage of Technics’ new generation of direct drive turntables that aim for further improvements in sound quality.

Features

New Motor-Drive System, ΔΣ-Drive (Delta Sigma Drive)

The ΔΣ-Drive is a new system that applies Technics’ expertise in PWM signal processing. In addition to reducing high harmonics, the new drive suppresses vibrations from the motor for smoother, more accurate rotation, ensuring a rich reproduction of the music.

The First Stage of The New Generation of Technics’ Direct Drive Turntables

Since inventing the world’s first direct drive turntable, Technics has continued to work to improve sound quality. It has now developed the ΔΣ-Drive, which suppresses minute vibrations from the motor and improves the electromagnetic conversion accuracy of the cartridge. The first stage of direct drive turntable systems featuring this technology is the SL-1200GR2.

Coreless Direct Drive Motor Achieving Stable Rotation

In 1970, Technics commercialized the world‘s first direct drive turntable, and the system took the world by storm. Unlike belt drive and other systems, direct drive systems rotate the motor at low speed and directly drive the platter, thus providing numerous advantages, such as the almost complete absence of degradation in S/N ratio due to motor vibration and deceleration mechanisms, as well as high reliability over a long period time because of not requiring parts replacement.

And in 2016, Technics developed the twin-rotor, surface-facing, coreless direct drive motor with rotor magnets placed on both sides, thereby eliminating the rotation irregularity of the motor, referred to as "cogging," which was a unique issue for direct drive systems. This motor was adopted for the SL-1200G, which once again drew a significant response in the hi-fi market. The SL-1200GR2 inherits the same design philosophy with the new development of a single-rotor, surface-facing, coreless direct drive motor, resulting in the elimination of cogging.

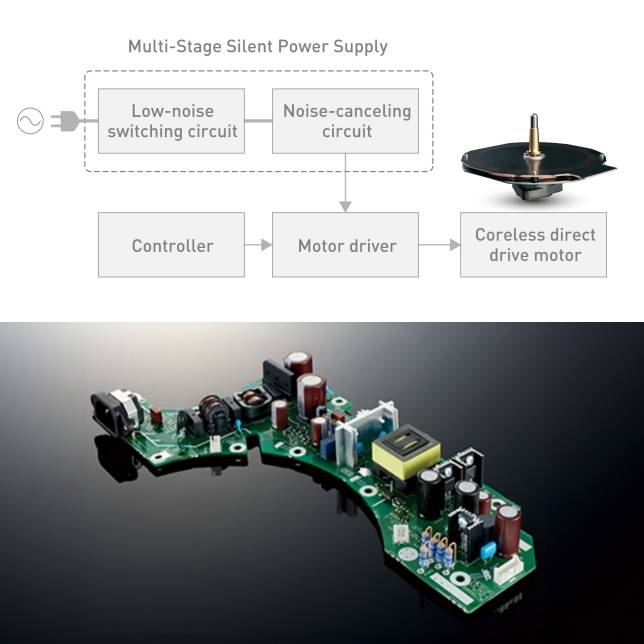

Multi-Stage Silent Power Supply

Low-Noise Switching Circuit

Use of a high-speed switching power supply ensures a stable supply capacity and less ripple and humming. Applying a switching power supply to a turntable eliminates the need for a large transformer and countermeasures for the ensuing mechanical vibrations.

A switching frequency of above 100 kHz limits the impact of noise on the music playback bandwidth.

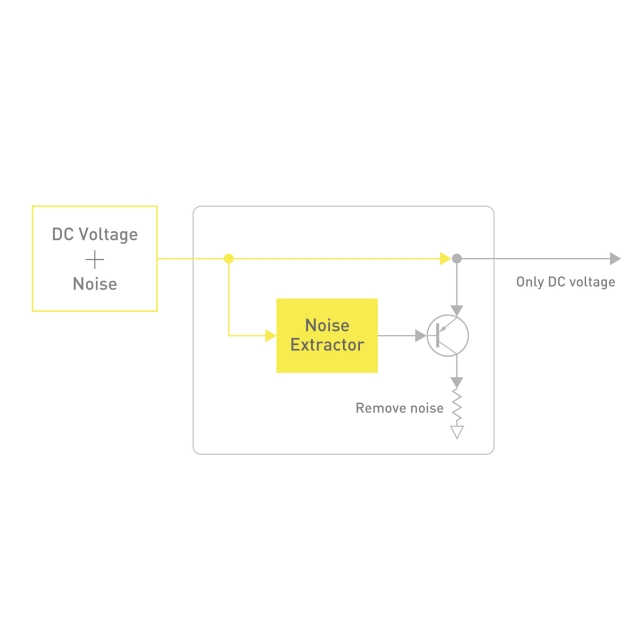

Current Injection Active Noise Cancelling

This technology combines a noise detection device with an error amplifier. It detects residual noise in the power supply and applies an inverse phase current to remove noise components. It removes low frequency noise more effectively than a regulator to ensure a more ideal power supply.

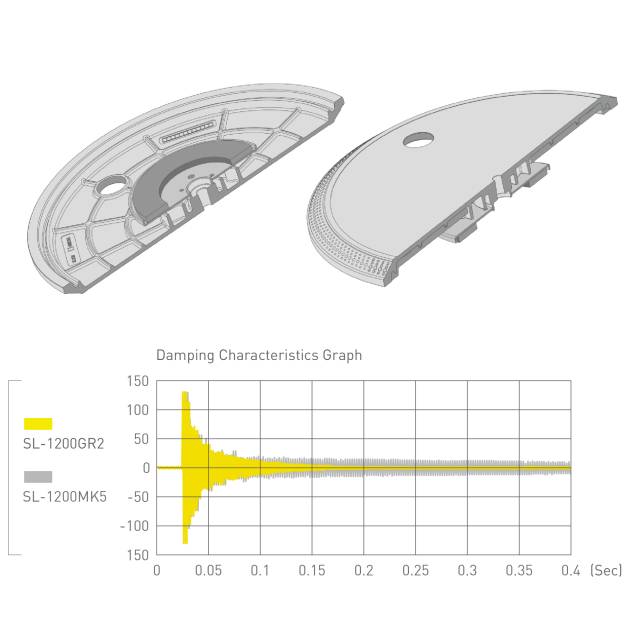

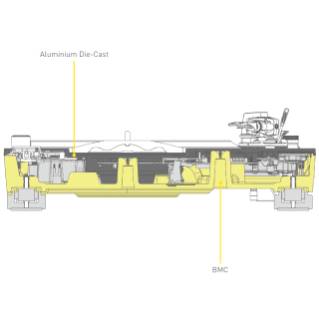

Pursuing Rigidity and Vibration Damping Characteristics

The platter achieves high rigidity and vibration damping characteristics by using a two-layer construction with deadening rubber applied to the entire rear surface of the aluminium die-cast to eliminate the unnecessary resonance that is otherwise relayed to the record, thereby producing clear sound.

To increase the inertial mass and reduce vibration, the shape of the aluminium die-cast portion was optimized by simulation. At 2.5 kg (including the rubber mat), the SL-1200GR2 platter is 0.8 kg heavier than that of the previous SL-1200MK5. Also, the back surface of the platter has strengthening ribs added to improve rigidity. Increasing the surface area of contact with the deadening rubber achieves damping characteristics that are more than twice those of the SL-1200MK5.

Tonearm Achieving High Initial-Motion Sensitivity

The tonearm tracks the rotation of the record and enables reading with high precision, and the tonearm inherited by Technics is the traditionally used static-balance universal S-shaped tonearm, employing an aluminium pipe with excellent light weight and rigidity for the material of the tonearm pipe.

With its gimbal suspension construction, the tonearm bearing section uses a cut-processed housing that employs high-precision bearings, as in the SL-1200G and SL-1200GR. The high initial-motion sensitivity of 5 mg or less is achieved through manual assembly and adjustment by skilled Japanese artisans. This enables the grooves etched into the records to be accurately traced.

In addition, one type of auxiliary weight comes included, and the cartridge can be swapped with a variety of other cartridges to match the music genre or feeling. (Applicable cartridge weight when using the supplied auxiliary weight: 10 - 16.4 g (not including the supplied head shell))

High-Grade Parts

Two-Layered Cabinet Construction

The SL-1200GR2 ensures high rigidity by using a body with a two-layered construction that solidly unifies the BMC and the aluminium die-cast chassis.

High-Damping Silicon Insulators

For the insulators supporting the body, the SL-1200GR2 uses special silicon rubber that ensures high vibration damping characteristics and long-term reliability.

High-Quality Terminals

The turntable uses gold-plated phono terminals for detachable cables, while metal shielding construction inside the case reduces the effects of external noise.

| Turntable section | |

|---|---|

| Drive Method | Direct Drive |

| Motor | Brushless DC motor |

| Turntable Speeds | 33-1/3, 45 and 78 rpm |

| Pitch Adjustment Range | ±8% and ±16% |

| Starting Torque | 2.2 kg・cm |

| Build-up Characteristics | 0.7 s. from standstill to 33- 1/3 rpm |

| Braking system | Electronic brake |

| Wow and Flutter | 0.025% W.R.M.S. |

| Turntable Platter | Aluminum diecast Diameter:332mm (13-5/64") Weight:Approx. 2.5kg (5.51lbs) (Including a rubber sheet) |

| Tonearm section | |

| Type | Static Balance |

| Effective Length | 230mm (9-1/16") |

| Overhang | 15mm (19/32") |

| Tracking Error Angle |

Within 2° 32' (at the outer groove of 30cm(12") record) Within 0° 32' (at the inner groove of 30cm(12") record) |

| Offset Angle | 22° |

| Arm Height Adjustment Range | 0 - 6mm (0"-15/64") |

| Stylus Pressure Adjustment Range | 0 - 4g (Direct Reading) |

| Headshell weight | Approx. 7.6g |

| Applicable Cartridge Weight Range | (without auxiliary weight) 5.6 - 12.0g 3.1 - 9.5g (using cartridge spacer) 14.3 - 20.7g (including head shell) (with auxiliary weight) 10.0 - 16.4g 7.5 - 13.9g (using cartridge spacer) 18.7 - 25.1g (including head shell) |

| Cartridge Mounting Dimension | 12.7 mm (1/2") interval |

| Head Shell Terminal Lug | 1.2mmφ 4-pin terminal lug |

| Terminals | |

| Audio Output |

PHONO (Pin Jack) x 1 EARTH TERMINAL x 1 |

| General | |

| Power Supply | AC120 V, 60 Hz |

| Power Consumption |

11 W (Power ON) 0.2 W (Power OFF) |

| Dimensions (W x H x D) |

453 x 173 x 372 mm 17-27/32" × 6-13/16" × 14-21/32" inch |

| Weight |

Approx. 11.5kg 25.4lbs |

| Operating temperature range | 0℃ to +40℃ (+32°F to +104°F) |

| Operating humidity range | 35% to 80% RH (no condensation) |

| Accessories | Turntable, Turntable sheet, Dust cover, EP record adaptor, Balance weight, Auxiliary weight, Cartridge spacer Head shell, Overhang gauge, Screw set for cartridge, PHONO cable, PHONO earth lead, AC power supply cord, Owner's Manual |

Write a review

Featured Products

PJ07689273

PJ50435315

SL1210GR2K

PJ50435360

SL1200GR2S

PJ50438170

PJ97829542

PJ97823250

PJ35829405

PJ97823229

PJ71652005

Or as low as $240.73/month over 12 months.

Or as low as $240.73/month over 12 months.